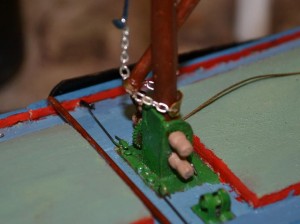

Dave and Tony Brooks are making some good progress on the major components of the Westmoreland model’s rigging. It seems they are raiding their ladies’ jewellery boxes for some realistically sized chain. Brave lads!

As Dave says, “We have now hung the sprit complete with muzzle and stanliff. It swings like the real thing. We have a temporary stayfall to ensure the mast stays upright. We also have a fid for the topmast so we can house that as well. Stayfall Tackle and shrouds are next. Got to come up with a way to make little dead eyes”.

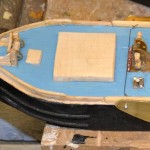

Incidentally, I think I never posted an earlier update from Dave dated 13th Feb, as follows, “Even though it was extremely cold we managed to move the model forward tonight. We have now permanently fitted our home made anchor having raided Dad’s wife’s jewellery box for a better chain. We also have bow badges that are as yet not painted. We fitted a bracket to the stem post for the anchor to chain to pass through and have put three turns of chain around the windlass. All that remains is for a small anchor chain box to be made which is housed just in front of the forward hatch.